As part of Wessex Community Asset’s work to develop the bioregional economy in SW England, we held a workshop on hemp fibre with 30 participants at our workspace in West Dorset. The process begins with separating (“decorticating”) the outer bast fibre from the woody core (the shiv), either manually with a hemp break or with our Hurdmaster decortication machine. The fibre is then cleaned (“scutched” and “heckled”) by dragging bundles through combs of different sizes – we used clusters of nails for the initial stages and then down to fine combs. At this point, the fibre can be spun, and Ellen Simon from Tamarisk Farm joined us to show people how to do this. Finally, Alexandra Carr from the University of Plymouth had made small looms in the digital fabrication lab, using a laser cutter on thin plywood, and encouraged participants to have a go at weaving. Everyone seemed to really enjoy the morning, and by the end the thick stems of hemp straw had been turned into beautiful gold thread. Read on for our thoughts on the implications for developing a bioregional textile economy.

There is a growing interest in the use of locally grown “bioregional” materials in the making of textiles. However, at the moment, many of the initiatives are operating at the craft or artisanal level, so there is less incentive for farmers to grow regenerative crops such as hemp or flax, and there is a challenge in financing appropriate processing facilities as the potential markets are undeveloped.

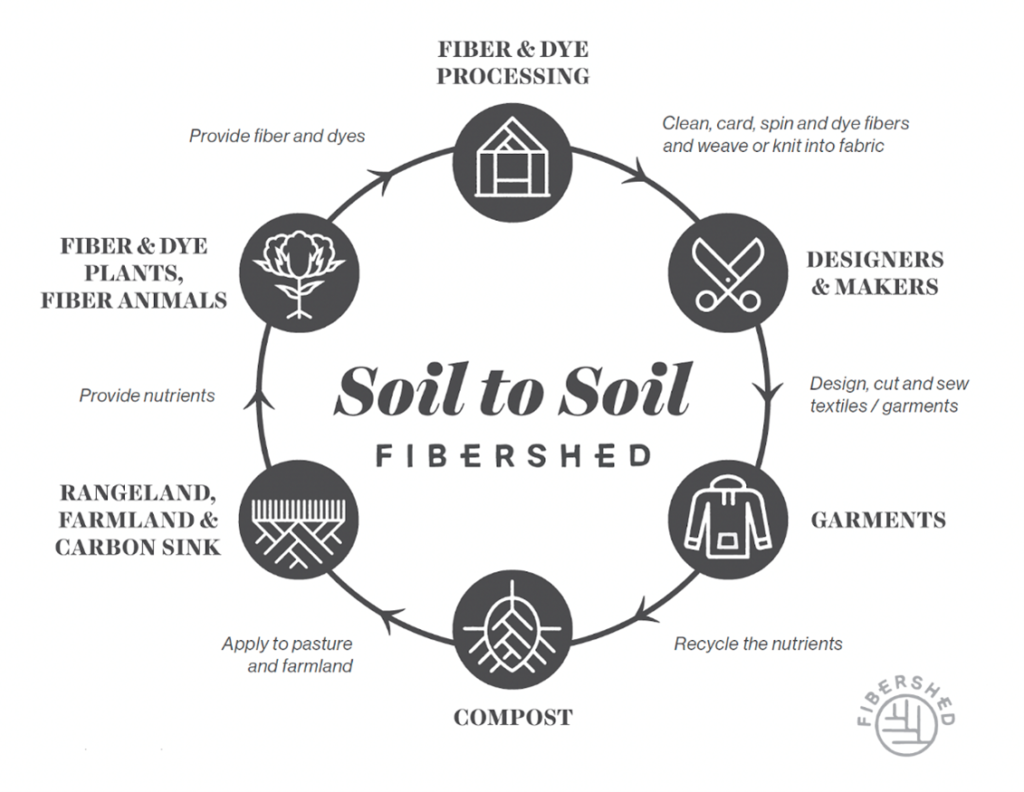

In the US, there is a growing “fibreshed” movement (https://fibershed.org/), which aims to support the development of bioregional fibre production – for textiles but also for other uses such as natural fibre insulation. Fibreshed groups are also developing in the UK (https://www.southwestenglandfibreshed.co.uk/ ). However, any attempt to develop a bioregional fibreshed must face up to a current situation that is hundreds of years in the making – from the forced enclosures that underpinned the production of wool and displaced rural dwellers to new factories in industrial cities, to the waves of de-industrialisation and globalisation in the twentieth century that shifted production to the Indian sub-continent and the Far East.

However, we now know that the textile and associated fashion industry is responsible for around 10% of global carbon dioxide emissions; it uses nearly 80 trillion litres of water annually; only 1% of garments are recycled; and waste from textile treatment and dyeing is responsible for 20% of industrial water pollution. 90% of the world’s clothing is produced in low- and middle-income countries. The average monthly wage of a worker in the global garment industry is €50, and 75% of global garment workers are women. See https://textileexchange.org/ for more information.

The fashion and textile industry in England, Wales and Scotland employs 500,000 people, made up of 88,000 employed in manufacturing, 62,000 in wholesale, and 413,000 in retail. 4,200 businesses are manufacturing textiles in the UK. UK households bought £57 billion worth of clothing in 2022. The UK imported £21 billion of clothes in 2022, along with £6.3 billion of textile fabric and £545 million of textile fibre. These are wholesale prices, which means that imports make up the majority of clothes sold in the UK.

So the question is, how might this reliance on the global fashion market be reduced, and what would be the potential benefits? One person who addressed this issue was the economist Jane Jacobs, who developed the concept of import substituting cities. Jacobs argued that the economies of cities thrived where a complex network of organisations and enterprises was able to substitute imports for goods and services produced in that settlement. Jacobs saw the rural hinterland as a supplier of raw materials – and young people – into the cities, but felt that smaller towns would not be able to emulate this import substitution strategy.

However, our experience at Wessex Community Assets does not support this sharp dichotomy between potentially vibrant cities and dependent rural hinterlands. Wessex has supported local communities in smaller towns and villages to develop local food networks, local energy systems, employment and training workspace as well as community housing initiatives for young families, thus helping to build resilient local economies in the more rural areas of the southwest.

In addition, we have been working with a range of partners to develop the production of natural materials produced and processed locally. Initially focused on timber and hemp for construction, we have also begun exploring the potential for local farmers to grow crops such as hemp and flax, which could be used to make textiles. This could boost the local economy and create local infrastructure and employment. However, in an acknowledgement of Jane Jacobs arguments about the importance of cities, it is recognised that the markets for these products cannot just be in Bridport, or even across Dorset, but that links to potential markets in cities across the South West will be essential. Moreover, it is also recognised that the expertise and experience required to develop these products will not all be found locally. So while there is a need to develop “small and local” approaches in a rural context, Wessex is also committed to being “open and connected” to larger urban areas in the southwest and beyond. Tim Crabtree